Comprehensive Guide to Steel Turned Parts in Precision Manufacturing

Release Time:

Aug 04,2025

In the realm of manufacturing and precision machining, steel turned parts play a crucial role in various applications. These components are typically produced using a lathe, where a piece of steel is rotated against a cutting tool to create precise geometries. Understanding the intricacies of steel turned parts can significantly enhance project outcomes and operational efficiency. Steel turned par

In the realm of manufacturing and precision machining, steel turned parts play a crucial role in various applications. These components are typically produced using a lathe, where a piece of steel is rotated against a cutting tool to create precise geometries. Understanding the intricacies of steel turned parts can significantly enhance project outcomes and operational efficiency.

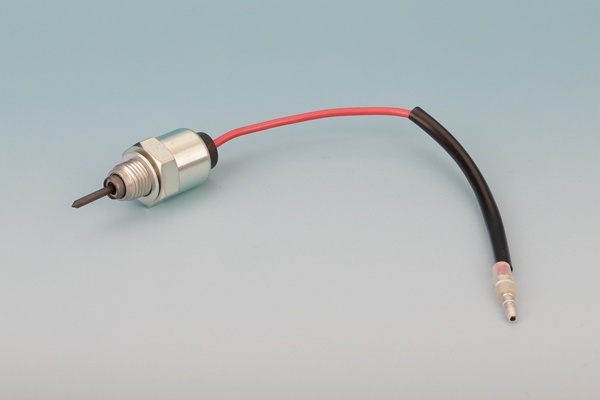

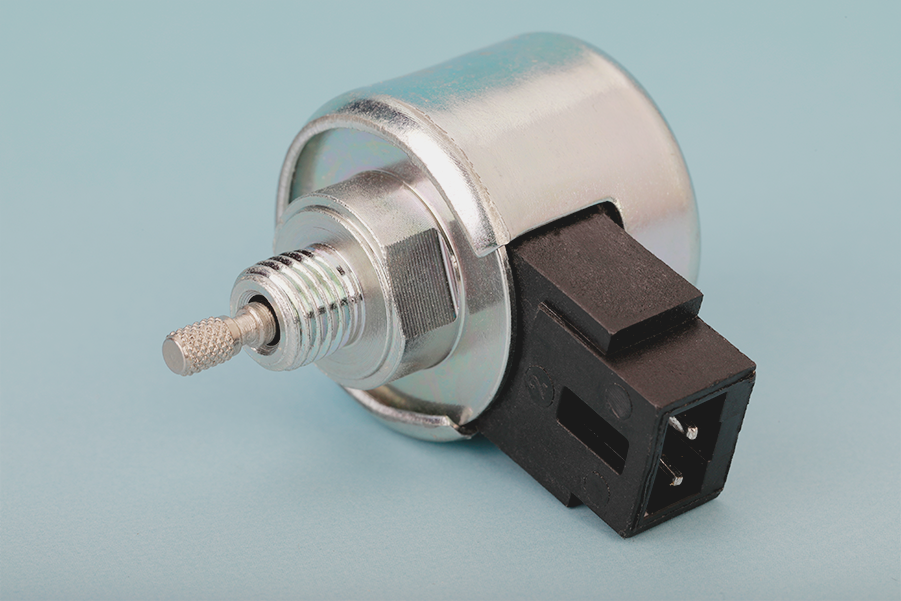

Steel turned parts are renowned for their durability, strength, and versatility. They are commonly used in sectors like automotive, aerospace, and industrial machinery. The ability to produce highly accurate components is one of the primary reasons why many manufacturers prefer steel turned parts. With minimal tolerances, these components can meet stringent specifications essential for high-performance applications.

The manufacturing process of steel turned parts involves several stages. Initially, raw steel is selected based on the desired properties of the final product. Once the steel is prepared, it is placed on a lathe machine. The lathe's cutting tool then shapes the steel into the required dimensions by removing excess material. This process allows for the production of parts with complex geometries, including threads, grooves, and contours.

One of the key benefits of using steel turned parts is their customization. Engineers can design parts that adhere to specific operational requirements, enhancing the performance and functionality of the final assembly. Additionally, the use of advanced CNC (Computer Numerical Control) lathes has revolutionized the manufacturing of steel turned parts. CNC technology allows for automated and precise machining, reducing human error and increasing production rates.

Furthermore, steel's inherent properties contribute to the longevity and reliability of turned parts. Steel has excellent tensile strength and resistance to wear and tear, making it a preferred material in high-stress environments. This durability translates into lower maintenance costs and extended service life for machinery and equipment.

In conclusion, steel turned parts are indispensable in the manufacturing industry, providing a perfect combination of strength, precision, and customization. Understanding how these components are produced and their applications can empower manufacturers to make informed decisions that enhance product quality and operational efficiency. Whether you are designing components for automotive systems or intricate aerospace structures, steel turned parts are likely to be at the core of your manufacturing needs. As the industry continues to evolve, the demand for high-quality, precisely engineered steel turned parts will remain paramount.

Steel turned parts are renowned for their durability, strength, and versatility. They are commonly used in sectors like automotive, aerospace, and industrial machinery. The ability to produce highly accurate components is one of the primary reasons why many manufacturers prefer steel turned parts. With minimal tolerances, these components can meet stringent specifications essential for high-performance applications.

The manufacturing process of steel turned parts involves several stages. Initially, raw steel is selected based on the desired properties of the final product. Once the steel is prepared, it is placed on a lathe machine. The lathe's cutting tool then shapes the steel into the required dimensions by removing excess material. This process allows for the production of parts with complex geometries, including threads, grooves, and contours.

One of the key benefits of using steel turned parts is their customization. Engineers can design parts that adhere to specific operational requirements, enhancing the performance and functionality of the final assembly. Additionally, the use of advanced CNC (Computer Numerical Control) lathes has revolutionized the manufacturing of steel turned parts. CNC technology allows for automated and precise machining, reducing human error and increasing production rates.

Furthermore, steel's inherent properties contribute to the longevity and reliability of turned parts. Steel has excellent tensile strength and resistance to wear and tear, making it a preferred material in high-stress environments. This durability translates into lower maintenance costs and extended service life for machinery and equipment.

In conclusion, steel turned parts are indispensable in the manufacturing industry, providing a perfect combination of strength, precision, and customization. Understanding how these components are produced and their applications can empower manufacturers to make informed decisions that enhance product quality and operational efficiency. Whether you are designing components for automotive systems or intricate aerospace structures, steel turned parts are likely to be at the core of your manufacturing needs. As the industry continues to evolve, the demand for high-quality, precisely engineered steel turned parts will remain paramount.

Related content