A Comprehensive Guide to Stainless Steel Grades for CNC Machining Parts

Release Time:

Aug 01,2025

A Comprehensive Guide to Stainless Steel Grades for CNC Machining Parts Table of Contents 1. Understanding Stainless Steel: An Overview 2. Why Stainless Steel is Ideal for CNC Machining Parts 3. Key Properties of Stainless Steel 3.1 Corrosion Resistance 3.2 Strength and Durability 3.3 Thermal Properties 4. Common Grades of Stainless Steel Used in CNC Machining 4.1 304 Stainless Steel: The Most Ver

A Comprehensive Guide to Stainless Steel Grades for CNC Machining Parts

Table of Contents

1. Understanding Stainless Steel: An Overview

2. Why Stainless Steel is Ideal for CNC Machining Parts

3. Key Properties of Stainless Steel

3.1 Corrosion Resistance

3.2 Strength and Durability

3.3 Thermal Properties

4. Common Grades of Stainless Steel Used in CNC Machining

4.1 304 Stainless Steel: The Most Versatile Grade

4.2 316 Stainless Steel: Enhanced Corrosion Resistance

4.3 410 Stainless Steel: A Good Choice for Heat Treatment

4.4 420 Stainless Steel: High Hardness and Wear Resistance

4.5 430 Stainless Steel: Cost-Effective and Good for Aesthetic Applications

5. Factors Influencing the Selection of Stainless Steel Grades

6. CNC Machining Techniques for Stainless Steel

6.1 Recommended Tools and Equipment

6.2 Setup and Machining Parameters

7. Common Applications of Stainless Steel Machined Parts

8. FAQs: Your Questions Answered

9. Conclusion

1. Understanding Stainless Steel: An Overview

Stainless steel is an alloy known for its remarkable corrosion resistance and high strength. It comprises iron, chromium, and, in some cases, nickel and other elements that enhance its properties. The durability and aesthetic appeal of stainless steel make it a favored choice for various applications, especially in CNC machining.

2. Why Stainless Steel is Ideal for CNC Machining Parts

Stainless steel is favored in CNC machining due to its impressive mechanical properties and versatility. Its ability to withstand harsh conditions while maintaining structural integrity makes it perfect for high-precision parts. Furthermore, stainless steel's compatibility with various machining processes allows for intricate designs and the production of complex components.

3. Key Properties of Stainless Steel

To understand why stainless steel is widely used in CNC machining, we must explore its fundamental properties.

3.1 Corrosion Resistance

The most significant advantage of stainless steel is its corrosion resistance. The presence of chromium forms a passive layer of chromium oxide on its surface, protecting it from oxidation and rust. This makes it the preferred material for applications exposed to moisture and harsh chemicals.

3.2 Strength and Durability

Stainless steel possesses excellent tensile and yield strength, allowing it to withstand heavy loads and impacts. This durability ensures that machined parts maintain their shape and functionality over time.

3.3 Thermal Properties

Stainless steel has good thermal conductivity, making it suitable for applications that require heat resistance. Its ability to withstand extreme temperatures without deforming is crucial in various industries.

4. Common Grades of Stainless Steel Used in CNC Machining

Different grades of stainless steel offer varying properties, making some more suitable than others for specific applications in CNC machining.

4.1 304 Stainless Steel: The Most Versatile Grade

304 stainless steel is the most widely used grade due to its excellent combination of strength, corrosion resistance, and affordability. It's often used in food processing, chemical equipment, and architectural applications.

4.2 316 Stainless Steel: Enhanced Corrosion Resistance

316 stainless steel contains molybdenum, which significantly improves its resistance to corrosion, particularly in marine environments. It's ideal for chemical processing, marine applications, and medical devices.

4.3 410 Stainless Steel: A Good Choice for Heat Treatment

410 stainless steel is a ferritic grade that can be hardened through heat treatment. It's often used for applications requiring high wear resistance, such as cutlery and surgical instruments.

4.4 420 Stainless Steel: High Hardness and Wear Resistance

420 stainless steel provides excellent hardness and is often used for blades and cutting tools. Its ability to retain sharp edges makes it ideal for applications where precision cutting is required.

4.5 430 Stainless Steel: Cost-Effective and Good for Aesthetic Applications

430 stainless steel is often chosen for its aesthetic appeal and affordability. It's commonly used in household appliances, automotive trim, and decorative applications.

5. Factors Influencing the Selection of Stainless Steel Grades

When selecting a stainless steel grade for CNC machining, several factors need to be considered:

- **Corrosion Resistance**: Determine the environment in which the parts will be used and select a grade that offers adequate protection.

- **Mechanical Properties**: Assess the required strength, ductility, and toughness of the part to ensure it meets performance expectations.

- **Cost**: Consider the budget for materials, as prices can vary significantly between different stainless steel grades.

- **Machinability**: Some stainless steel grades are easier to machine than others, which can affect production efficiency and costs.

6. CNC Machining Techniques for Stainless Steel

CNC machining stainless steel requires precise techniques to ensure high-quality output. Here are some recommended practices:

6.1 Recommended Tools and Equipment

Using the right tools is crucial for machining stainless steel effectively. Carbide tools, high-speed steel, and specialized coatings can enhance performance. Ensure that machinery is equipped with adequate power and precision controls.

6.2 Setup and Machining Parameters

Proper setup is essential. Consider the following parameters:

- **Feed Rate**: A slower feed rate is generally recommended for stainless steel to reduce tool wear.

- **Cutting Speed**: Optimal cutting speeds vary by grade; therefore, consult manufacturer guidelines.

- **Coolant**: Utilize coolant to dissipate heat and prolong tool life.

7. Common Applications of Stainless Steel Machined Parts

Stainless steel is used across various industries for its unique properties. Common applications include:

- **Medical Devices**: Surgical instruments, implants, and equipment.

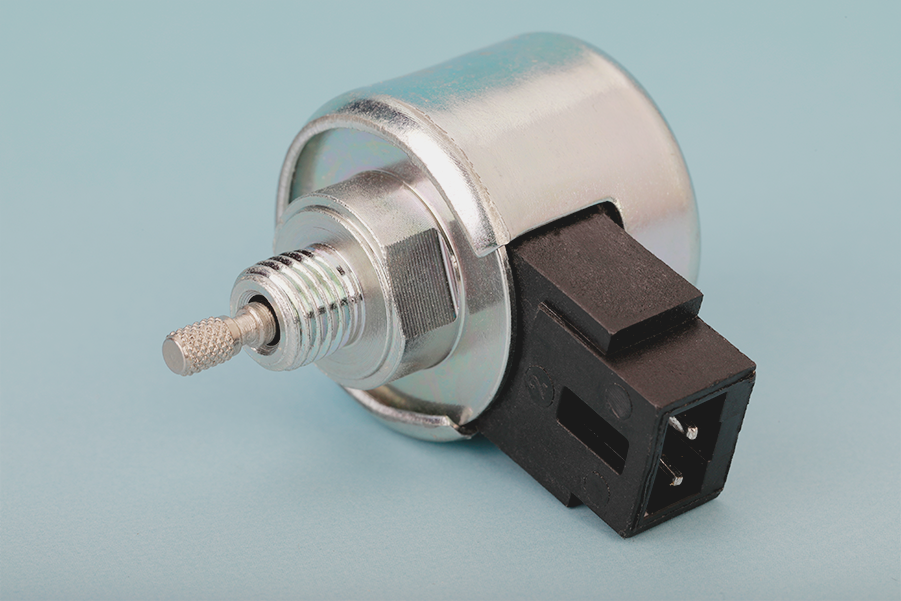

- **Automotive Parts**: Exhaust systems, trim, and structural components.

- **Food Processing**: Equipment that requires hygienic conditions and corrosion resistance.

- **Aerospace**: Engine components and structural parts that require high strength and lightweight properties.

8. FAQs: Your Questions Answered

What is the best stainless steel grade for CNC machining?

The choice of grade depends on the specific application, but 304 and 316 grades are typically the most popular due to their versatility and corrosion resistance.

How does the machinability of stainless steel compare to carbon steel?

Stainless steel generally has lower machinability compared to carbon steel, meaning it may require more careful handling and specialized tooling.

What are the signs of wear on machining tools when working with stainless steel?

Common signs include discoloration, chipping, and a rough surface finish on the machined parts.

Can all stainless steel types be heat treated?

Not all stainless steel grades can be heat treated. Generally, martensitic grades like 410 and 420 can be heat treated, while austenitic grades like 304 and 316 cannot.

What cooling methods are effective when machining stainless steel?

Using a flood coolant or mist coolant is effective in cooling the tool and workpiece during machining. It helps to dissipate heat and prolongs tool life.

9. Conclusion

Understanding the various grades of stainless steel and their properties is essential for selecting the right material for CNC machining parts. Each grade offers unique advantages, and the choice depends on the specific requirements of the intended application. By considering factors such as corrosion resistance, mechanical properties, and machinability, manufacturers can make informed decisions that enhance the performance and longevity of their products. As technology continues to evolve, staying informed about material properties and machining techniques will ensure success in the competitive landscape of manufacturing.