How to Effectively Troubleshoot Common Carburetor Solenoid Problems

Release Time:

Jul 05,2025

How to Effectively Troubleshoot Common Carburetor Solenoid Problems Table of Contents Understanding Carburetor Solenoids Common Symptoms of Solenoid Issues Essential Tools for Diagnosis Step-by-Step Troubleshooting Guide Testing the Solenoid Common Repairs and Solutions When to Seek Professional Help Preventative Maintenance Tips Conclusion FAQs Understand

How to Effectively Troubleshoot Common Carburetor Solenoid Problems

Table of Contents

- Understanding Carburetor Solenoids

- Common Symptoms of Solenoid Issues

- Essential Tools for Diagnosis

- Step-by-Step Troubleshooting Guide

- Testing the Solenoid

- Common Repairs and Solutions

- When to Seek Professional Help

- Preventative Maintenance Tips

- Conclusion

- FAQs

Understanding Carburetor Solenoids

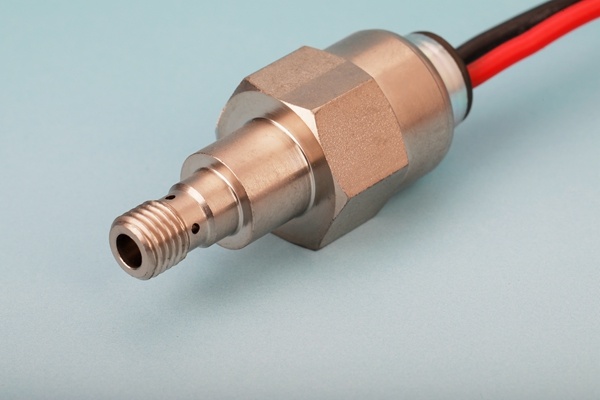

Carburetor solenoids play a crucial role in controlling the fuel-air mixture in internal combustion engines. These electromechanical devices open and close valves, regulating fuel flow and ensuring optimal engine performance. Understanding their function is vital for diagnosing problems accurately.

The Role of Carburetor Solenoids

Carburetor solenoids are primarily responsible for the activation of fuel systems within the carburetor. When the engine is running, the solenoid opens to allow fuel to mix with air, facilitating combustion. If the solenoid fails, it can disrupt this balance, leading to performance issues.

Common Symptoms of Solenoid Issues

Identifying the symptoms of a malfunctioning carburetor solenoid is the first step in troubleshooting. Here are some common signs to look for:

1. Engine Stalling

If your engine stalls unexpectedly, it may be due to a solenoid that is failing to open or close properly. This interruption can cause fuel flow issues, leading to stalling.

2. Poor Acceleration

When you press the accelerator pedal, a sluggish response can indicate that the carburetor solenoid is not delivering adequate fuel to the engine. This can affect overall performance and driveability.

3. Engine Misfiring

Misfires happen when there's an incorrect air-fuel mixture in the combustion chamber. A faulty solenoid may prevent the proper amount of fuel from entering the mixture, resulting in misfires.

4. Inconsistent Idling

Erratic idling can signal solenoid problems. If the solenoid fails to maintain the correct fuel flow, the engine may idle roughly or at inconsistent RPMs.

Essential Tools for Diagnosis

Dedicating time to gather the right tools will streamline your troubleshooting process. Here’s a list of essential tools to have on hand:

- Multimeter

- Socket set

- Screwdrivers (flathead and Phillips)

- Fuel pressure gauge

- Diagnostic scanner

- Wiring diagram for your vehicle model

Step-by-Step Troubleshooting Guide

Follow this comprehensive guide to troubleshoot your carburetor solenoid issues effectively:

Step 1: Visual Inspection

Begin with a thorough visual inspection of the carburetor and solenoid. Look for signs of damage, corrosion, or disconnections in the wiring. A damaged solenoid will often show physical wear.

Step 2: Check Electrical Connections

Ensure that all electrical connections to the solenoid are secure. Loose or corroded connections can interrupt the electrical flow, hindering solenoid operation.

Step 3: Test the Solenoid with a Multimeter

Using a multimeter, check the solenoid's resistance. A reading outside the manufacturer’s specifications suggests a faulty solenoid that may need replacement.

Step 4: Evaluate Fuel Supply

Verify that the fuel supply to the carburetor is adequate. Use a fuel pressure gauge to check for proper pressure levels, ensuring the solenoid can function effectively.

Step 5: Inspect for Blockages

Check for any blockages in the fuel lines or carburetor that could hinder fuel flow. Clean any debris or buildup that may be causing issues.

Testing the Solenoid

Testing the carburetor solenoid is critical in ensuring it operates correctly. Follow these steps for accurate testing:

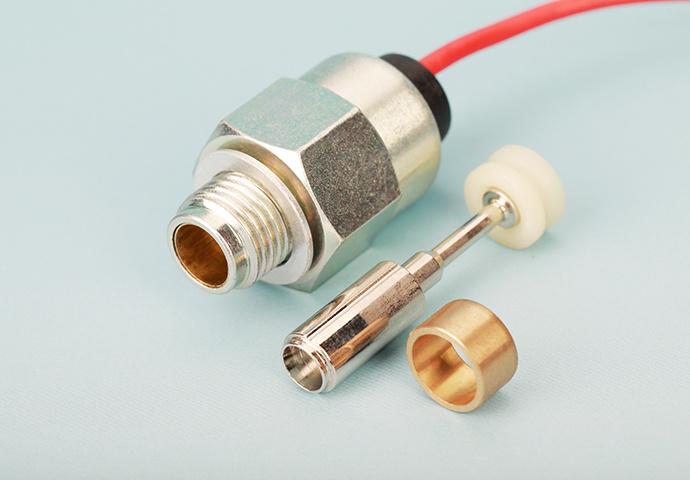

1. Disconnect the Solenoid

With the engine off, disconnect the solenoid from its electrical connector to safely assess its functionality.

2. Check for Continuity

Set your multimeter to the continuity setting. Place the probes on the solenoid terminals. A beep indicates continuity, confirming that the solenoid can receive power.

3. Apply Voltage

While the solenoid is disconnected, apply voltage directly to it. Listen for a click sound, which indicates that the solenoid is working. If no sound is heard, consider replacement.

Common Repairs and Solutions

Once you have identified the problem, several repairs can be performed:

1. Cleaning Connections

If corrosion is present on the electrical connectors, cleaning them may restore functionality. Use electrical cleaner or contact cleaner for optimal results.

2. Replacing the Solenoid

If testing indicates that the solenoid is faulty, replacement is necessary. Ensure you purchase a compatible solenoid specific to your vehicle model.

3. Repairing Wiring

Damaged wiring should be repaired or replaced to ensure proper electrical flow. This may involve soldering or using wire connectors.

When to Seek Professional Help

While troubleshooting carburetor solenoid problems can often be managed independently, some situations may require professional assistance:

- Inability to isolate the issue after thorough testing.

- Complex electrical issues that may affect other vehicle systems.

- Lack of experience with repairs or comfort level with automotive work.

Preventative Maintenance Tips

To prolong the life of your carburetor solenoid and prevent future issues, consider the following maintenance tips:

1. Regular Inspections

Conduct routine checks of the carburetor and surrounding components to catch signs of wear early.

2. Clean Fuel System

Keep the fuel system clean by using quality fuel and adding fuel system cleaners periodically to prevent buildup.

3. Follow Recommended Service Intervals

Adhere to your vehicle’s maintenance schedule to ensure that all components, including solenoids, are serviced appropriately.

Conclusion

Troubleshooting common carburetor solenoid problems is a manageable task when armed with the right knowledge and tools. By recognizing symptoms, conducting thorough inspections, and performing tests, you can diagnose and fix issues efficiently. Regular maintenance and prompt repairs will ensure your vehicle operates at peak performance. When in doubt, consulting a professional mechanic can save time and trouble. Empower yourself with the insights shared in this guide, and take charge of your vehicle’s health today!

FAQs

1. What is a carburetor solenoid?

A carburetor solenoid is an electromechanical device that controls the flow of fuel in a carburetor, helping maintain the correct fuel-air mixture for combustion.

2. How do I know if my carburetor solenoid is bad?

Common signs include engine stalling, poor acceleration, inconsistent idling, and engine misfiring. Testing with a multimeter can confirm functionality.

3. Can I repair a carburetor solenoid myself?

Yes, many solenoid issues can be diagnosed and repaired with basic tools and automotive knowledge. However, complex problems may require professional help.

4. How often should I inspect my carburetor solenoid?

It’s advisable to check your carburetor solenoid during regular vehicle maintenance or if you notice performance issues.

5. What are some preventative measures for solenoid issues?

Regular inspections, keeping the fuel system clean, and following recommended maintenance schedules can help prevent solenoid problems.