Understanding Kohler Engine Fuel Solenoids: Key Components for Optimal Performance

Release Time:

Jul 02,2025

Kohler engines are renowned for their reliability and performance, widely used in various applications, from lawn mowers to industrial equipment. One critical component that plays an essential role in the functionality of these engines is the fuel solenoid. Understanding the purpose and operation of the Kohler engine fuel solenoid can help you ensure optimal performance and longevity of your equip

Kohler engines are renowned for their reliability and performance, widely used in various applications, from lawn mowers to industrial equipment. One critical component that plays an essential role in the functionality of these engines is the fuel solenoid. Understanding the purpose and operation of the Kohler engine fuel solenoid can help you ensure optimal performance and longevity of your equipment.

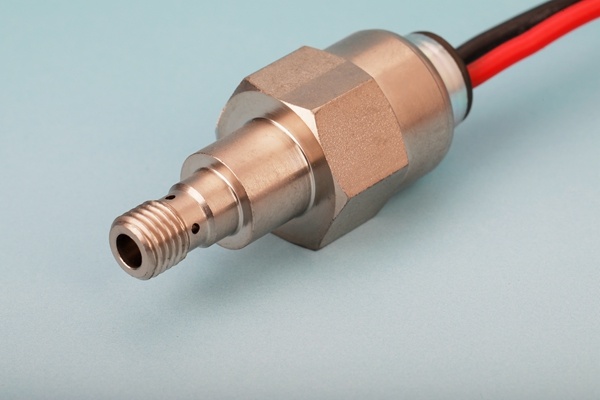

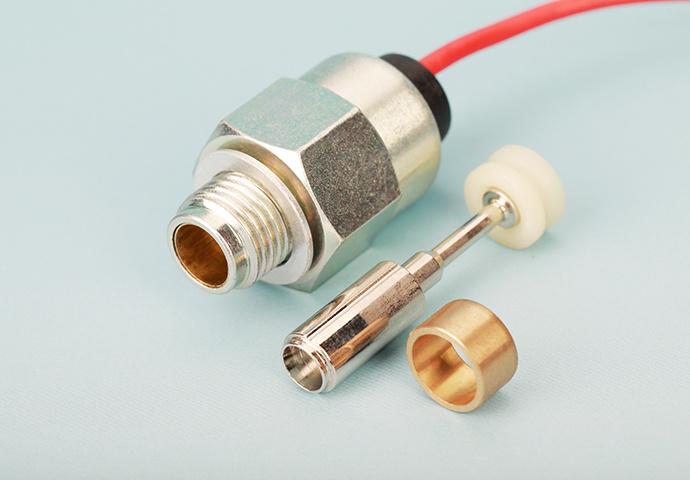

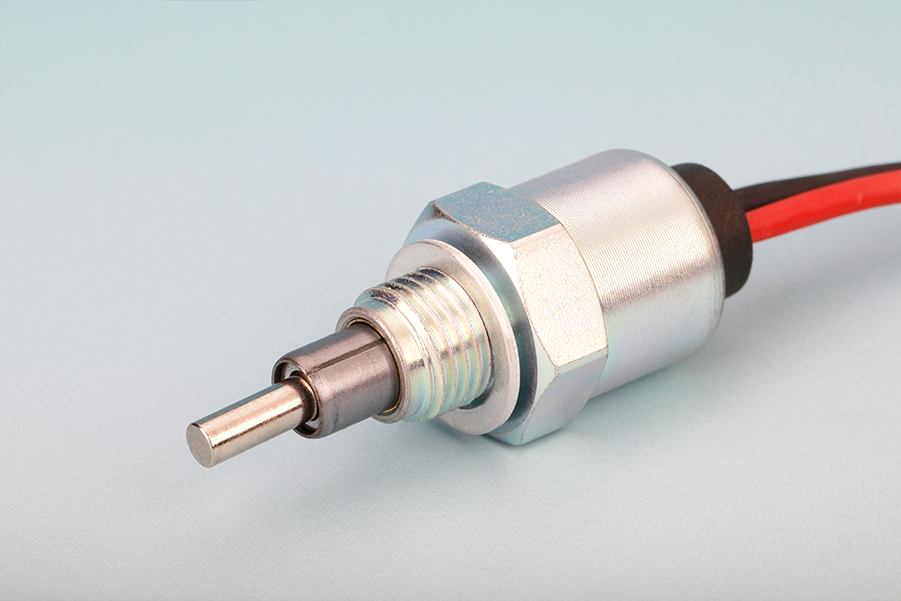

A fuel solenoid is an electromechanical device that controls the flow of fuel to the engine. It operates by using an electromagnetic coil that, when energized, moves a plunger to either open or close the fuel line. In Kohler engines, this solenoid is responsible for regulating the amount of fuel that enters the combustion chamber, which is crucial for engine efficiency, performance, and emissions control.

The proper functioning of the Kohler engine fuel solenoid is vital for several reasons. First, it ensures that the engine receives the correct fuel-to-air ratio, which is essential for efficient combustion. An improper ratio can lead to poor engine performance, reduced fuel efficiency, and increased emissions. Additionally, a malfunctioning fuel solenoid can result in starting issues or stalling, which can be frustrating for users and impact productivity.

Maintenance and troubleshooting of the Kohler engine fuel solenoid involve several steps. Regular inspection is important to ensure that the solenoid is clean and free from debris. Any dirt or buildup can impede its operation, leading to fuel flow issues. Additionally, checking the electrical connections for corrosion and ensuring that the solenoid is receiving the proper voltage can help prevent operational failures.

If you suspect that your Kohler engine fuel solenoid is malfunctioning, common symptoms may include difficulty starting the engine, erratic engine performance, or stalling. In such cases, testing the solenoid with a multimeter can help determine whether it is functioning correctly. If the solenoid is found to be defective, replacing it can restore the engine's performance.

In conclusion, the Kohler engine fuel solenoid is a vital component that significantly impacts engine performance, efficiency, and reliability. By understanding its function and maintaining it properly, users can ensure their equipment runs smoothly and efficiently. Whether you're a mechanic or an equipment owner, knowing how to care for and troubleshoot the fuel solenoid will lead to more effective maintenance and a longer lifespan for your Kohler engine.

A fuel solenoid is an electromechanical device that controls the flow of fuel to the engine. It operates by using an electromagnetic coil that, when energized, moves a plunger to either open or close the fuel line. In Kohler engines, this solenoid is responsible for regulating the amount of fuel that enters the combustion chamber, which is crucial for engine efficiency, performance, and emissions control.

The proper functioning of the Kohler engine fuel solenoid is vital for several reasons. First, it ensures that the engine receives the correct fuel-to-air ratio, which is essential for efficient combustion. An improper ratio can lead to poor engine performance, reduced fuel efficiency, and increased emissions. Additionally, a malfunctioning fuel solenoid can result in starting issues or stalling, which can be frustrating for users and impact productivity.

Maintenance and troubleshooting of the Kohler engine fuel solenoid involve several steps. Regular inspection is important to ensure that the solenoid is clean and free from debris. Any dirt or buildup can impede its operation, leading to fuel flow issues. Additionally, checking the electrical connections for corrosion and ensuring that the solenoid is receiving the proper voltage can help prevent operational failures.

If you suspect that your Kohler engine fuel solenoid is malfunctioning, common symptoms may include difficulty starting the engine, erratic engine performance, or stalling. In such cases, testing the solenoid with a multimeter can help determine whether it is functioning correctly. If the solenoid is found to be defective, replacing it can restore the engine's performance.

In conclusion, the Kohler engine fuel solenoid is a vital component that significantly impacts engine performance, efficiency, and reliability. By understanding its function and maintaining it properly, users can ensure their equipment runs smoothly and efficiently. Whether you're a mechanic or an equipment owner, knowing how to care for and troubleshoot the fuel solenoid will lead to more effective maintenance and a longer lifespan for your Kohler engine.

Related content