Understanding the Kohler Engine Fuel Solenoid: Essential Insights for Automotive Professionals

Release Time:

Apr 25,2025

The Kohler engine fuel solenoid is a vital component in various small engines, particularly those used in lawnmowers, generators, and other outdoor power equipment. Understanding the function and importance of this solenoid can significantly enhance maintenance practices and troubleshooting efforts for professionals in the automotive and electrical sectors. At its core, the fuel solenoid acts as a

The Kohler engine fuel solenoid is a vital component in various small engines, particularly those used in lawnmowers, generators, and other outdoor power equipment. Understanding the function and importance of this solenoid can significantly enhance maintenance practices and troubleshooting efforts for professionals in the automotive and electrical sectors.

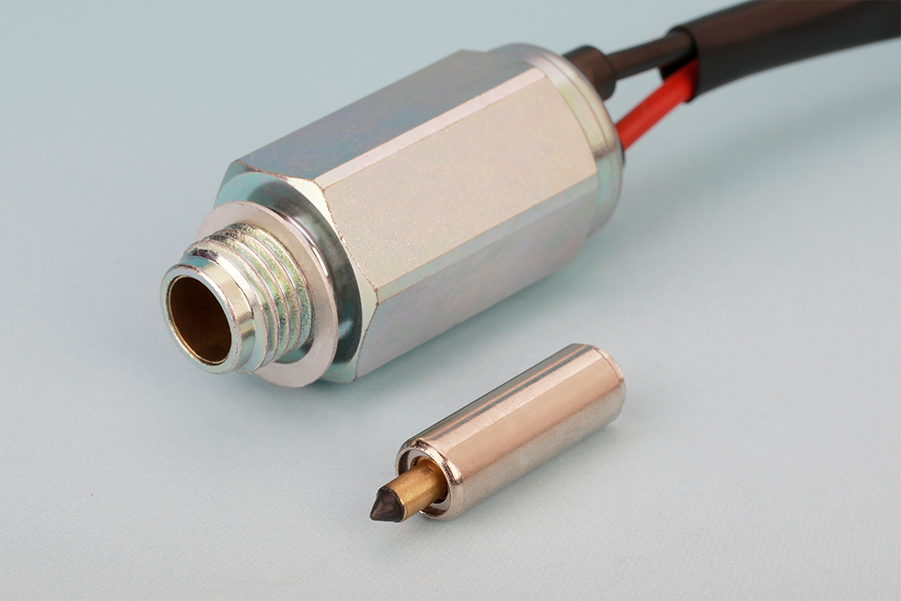

At its core, the fuel solenoid acts as an electromagnetic valve that controls the flow of fuel to the engine. When the engine is off or in a non-operational state, the solenoid is de-energized, which prevents fuel from entering the engine. This feature is crucial for preventing fuel leakage and ensuring that fuel is only supplied when the engine is running. When the ignition is turned on, the solenoid is activated, allowing fuel to flow through the system, which supports engine operation.

One of the key advantages of the Kohler engine fuel solenoid is its ability to enhance engine efficiency and performance. By ensuring precise fuel delivery, it helps maintain optimal fuel-air mixtures, contributing to better combustion, improved power output, and reduced emissions. For automotive professionals, understanding how to diagnose and troubleshoot issues related to the fuel solenoid is essential. Common problems include solenoid failure, which can manifest as engine stalling, difficulty starting, or erratic behavior during operation. Regular inspections can help identify wear or damage, ensuring reliable engine performance.

Installation and maintenance practices are critical when working with Kohler engine fuel solenoids. It is important to ensure that the solenoid is wired correctly and securely, as improper installation can lead to malfunction. Additionally, regular cleaning and inspection of electrical connections can prevent corrosion and ensure the solenoid operates effectively over time.

When replacing a Kohler engine fuel solenoid, professionals should consider factors such as compatibility with the specific engine model, as well as the quality of the replacement part. High-quality components will often result in longer service life and better performance.

In conclusion, the Kohler engine fuel solenoid plays a crucial role in the functionality and efficiency of small engines. By understanding its operation, benefits, and maintenance requirements, automotive professionals can improve their service quality, enhance engine performance, and provide better overall solutions for their clients. Whether dealing with routine maintenance or troubleshooting complex issues, knowledge of the fuel solenoid is indispensable for success in the automotive industry.

At its core, the fuel solenoid acts as an electromagnetic valve that controls the flow of fuel to the engine. When the engine is off or in a non-operational state, the solenoid is de-energized, which prevents fuel from entering the engine. This feature is crucial for preventing fuel leakage and ensuring that fuel is only supplied when the engine is running. When the ignition is turned on, the solenoid is activated, allowing fuel to flow through the system, which supports engine operation.

One of the key advantages of the Kohler engine fuel solenoid is its ability to enhance engine efficiency and performance. By ensuring precise fuel delivery, it helps maintain optimal fuel-air mixtures, contributing to better combustion, improved power output, and reduced emissions. For automotive professionals, understanding how to diagnose and troubleshoot issues related to the fuel solenoid is essential. Common problems include solenoid failure, which can manifest as engine stalling, difficulty starting, or erratic behavior during operation. Regular inspections can help identify wear or damage, ensuring reliable engine performance.

Installation and maintenance practices are critical when working with Kohler engine fuel solenoids. It is important to ensure that the solenoid is wired correctly and securely, as improper installation can lead to malfunction. Additionally, regular cleaning and inspection of electrical connections can prevent corrosion and ensure the solenoid operates effectively over time.

When replacing a Kohler engine fuel solenoid, professionals should consider factors such as compatibility with the specific engine model, as well as the quality of the replacement part. High-quality components will often result in longer service life and better performance.

In conclusion, the Kohler engine fuel solenoid plays a crucial role in the functionality and efficiency of small engines. By understanding its operation, benefits, and maintenance requirements, automotive professionals can improve their service quality, enhance engine performance, and provide better overall solutions for their clients. Whether dealing with routine maintenance or troubleshooting complex issues, knowledge of the fuel solenoid is indispensable for success in the automotive industry.

Related content