Maximizing Engine Performance with Kohler Carburetor Solenoids: A Comprehensive Guide

Release Time:

Apr 24,2025

Maximizing Engine Performance with Kohler Carburetor Solenoids Table of Contents 1. Introduction to Kohler Carburetor Solenoids 2. Understanding Carburetor Solenoids 3. The Role of Solenoids in Engine Performance 4. Benefits of Using Kohler Carburetor Solenoids 5. Installation Guide for Kohler Carburetor Solenoids 6. Maintenance Tips for Longevity 7. Troubleshooting Co

Maximizing Engine Performance with Kohler Carburetor Solenoids

Table of Contents

- 1. Introduction to Kohler Carburetor Solenoids

- 2. Understanding Carburetor Solenoids

- 3. The Role of Solenoids in Engine Performance

- 4. Benefits of Using Kohler Carburetor Solenoids

- 5. Installation Guide for Kohler Carburetor Solenoids

- 6. Maintenance Tips for Longevity

- 7. Troubleshooting Common Issues with Kohler Solenoids

- 8. Conclusion

- 9. FAQs

1. Introduction to Kohler Carburetor Solenoids

When it comes to maximizing engine performance, every component plays a crucial role. **Kohler carburetor solenoids** are integral to the function and efficiency of many engines, particularly in outdoor power equipment. These devices regulate the flow of fuel, ensuring optimal combustion and performance. In this article, we will delve into what carburetor solenoids are, their function, and how they can enhance your engine’s efficiency.

2. Understanding Carburetor Solenoids

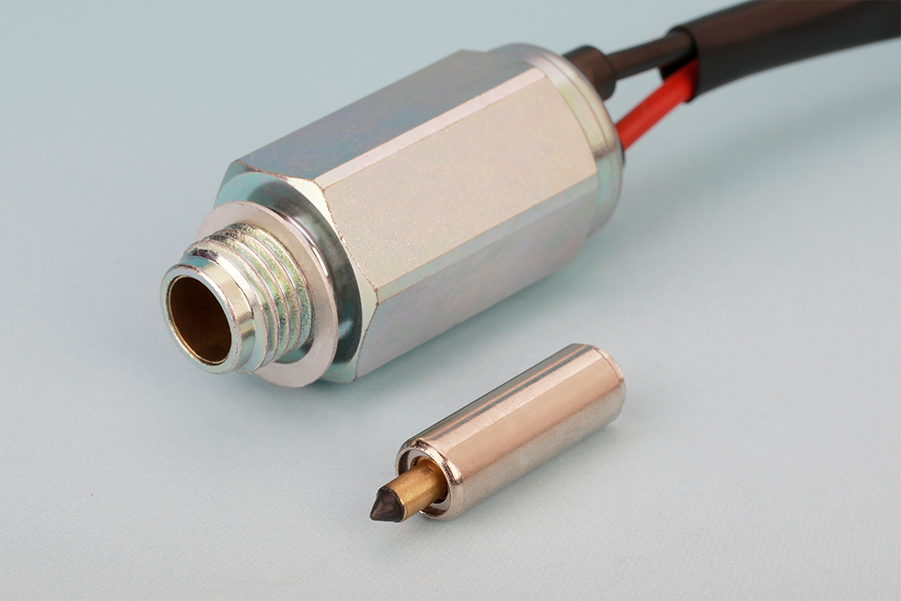

Carburetor solenoids are electromagnetic devices designed to control fuel flow to the engine. These solenoids open or close based on the electrical signals received from the engine's control unit. By adjusting the fuel supply, they play a crucial role in optimizing engine performance, fuel efficiency, and emissions.

The Mechanism Behind Carburetor Solenoids

The operation of carburetor solenoids is relatively straightforward. When the engine requires more fuel, an electrical signal activates the solenoid, opening the valve. This allows for a greater flow of fuel into the combustion chamber, which is essential for performance, especially during acceleration. Conversely, when less fuel is needed, the solenoid closes the valve, preventing excess fuel from entering the system.

3. The Role of Solenoids in Engine Performance

The performance of an engine is greatly influenced by the efficiency of its fuel delivery system. Kohler carburetor solenoids enhance performance by:

Optimizing Fuel-Air Mixture

A balanced fuel-air mixture is crucial for efficient combustion. Kohler solenoids ensure that the right amount of fuel is delivered based on engine demands, preventing issues such as flooding or lean conditions.

Improving Throttle Response

A quick throttle response is essential for a dynamic driving experience. By efficiently managing fuel flow, carburetor solenoids contribute to a snappier throttle response, allowing for improved acceleration and overall engine responsiveness.

Enhancing Engine Efficiency

By maintaining optimal fuel flow, Kohler solenoids help to maximize engine efficiency. This not only translates to better performance but also improved fuel economy, which is a significant concern for many engine users today.

4. Benefits of Using Kohler Carburetor Solenoids

There are several advantages to using Kohler carburetor solenoids in your engine, including:

1. Enhanced Performance

With precise fuel management, Kohler solenoids significantly boost engine performance, making them ideal for high-demand applications.

2. Fuel Efficiency

These solenoids help reduce fuel consumption by ensuring an optimal fuel-air mixture, leading to enhanced fuel economy and lower emissions.

3. Reliability and Durability

Kohler solenoids are built to last, providing consistent performance over time. Their durability reduces the need for frequent replacements, saving both time and money.

4. Compatibility with Various Engines

Kohler carburetor solenoids are versatile and can be used in a wide range of engine types, making them a popular choice for both residential and commercial applications.

5. Installation Guide for Kohler Carburetor Solenoids

Installing Kohler carburetor solenoids can be a straightforward process if you follow these steps:

Step 1: Gather Your Tools

Before beginning the installation, gather all necessary tools, including a wrench set, screwdrivers, and any additional items specified in the solenoid's manual.

Step 2: Disconnect the Battery

Safety is paramount. Disconnect the battery to prevent any electrical accidents during installation.

Step 3: Remove the Old Solenoid

Locate the existing solenoid connected to your carburetor. Carefully disconnect the wires and remove any screws holding it in place.

Step 4: Install the New Kohler Solenoid

Position the new Kohler carburetor solenoid in place, ensuring it aligns correctly with the carburetor. Secure it with screws and reconnect the electrical wires.

Step 5: Reconnect the Battery and Test

Once the new solenoid is installed, reconnect the battery. Start the engine and check for proper operation, ensuring the solenoid engages and disengages as needed.

6. Maintenance Tips for Longevity

To ensure your Kohler carburetor solenoids function optimally over time, follow these maintenance tips:

Regular Inspections

Periodically inspect the solenoids for signs of wear or damage. Look for frayed wires, corrosion, or leaks.

Clean Fuel System

Keep your fuel system clean by using quality fuel and adding fuel additives that help prevent gunk buildup in the carburetor.

Check Electrical Connections

Ensure that all electrical connections are secure and free from corrosion. Loose connections can lead to poor performance.

Follow Manufacturer's Recommendations

Always adhere to the manufacturer's guidelines regarding maintenance schedules and replacement intervals to ensure longevity.

7. Troubleshooting Common Issues with Kohler Solenoids

Even with proper maintenance, issues may arise with carburetor solenoids. Here are some common problems and their solutions:

1. Engine Stalling

If the engine stalls, it could be due to a faulty solenoid. Check for electrical issues or replace the solenoid if necessary.

2. Poor Throttle Response

If you experience sluggish acceleration, ensure the solenoid is functioning correctly and not stuck open or closed.

3. Fuel Leaks

Inspect the solenoid for signs of fuel leakage. If leaks are present, replace the solenoid immediately to prevent further issues.

4. Electrical Failures

Test the electrical connections and wiring harness for faults. Damaged wiring can lead to solenoid malfunction.

8. Conclusion

Maximizing engine performance is essential for enhancing efficiency, responsiveness, and overall driving pleasure. **Kohler carburetor solenoids** play a vital role in achieving these goals by managing fuel flow effectively. By understanding their function, benefits, and maintenance, you can ensure that your engine runs at its best. From installation to troubleshooting, maintaining your Kohler solenoids will lead to a reliable and high-performing engine for years to come.

9. FAQs

1. What is a carburetor solenoid?

A carburetor solenoid is an electromagnetic device that controls the flow of fuel to the engine based on electrical signals, optimizing performance.

2. How do I know if my solenoid is faulty?

Signs of a faulty solenoid include engine stalling, poor throttle response, and fuel leaks. Regular inspections can help identify issues early.

3. Can I install a Kohler carburetor solenoid myself?

Yes, the installation is relatively straightforward, but ensure you follow the manufacturer's instructions and safety precautions.

4. How often should I replace my carburetor solenoid?

Replacement intervals vary, but regular inspections and adherence to the manufacturer's guidelines can help determine when to replace your solenoid.

5. Will using Kohler solenoids really improve my engine performance?

Yes, Kohler carburetor solenoids are designed to enhance fuel efficiency, improve throttle response, and ultimately maximize engine performance.

Related content