Understanding Steel Turned Parts: Applications and Benefits in Precision Engineering

Release Time:

Apr 17,2025

Steel turned parts are vital components in various industries, especially within the realm of precision engineering and mechanical hardware processing. These parts typically undergo a manufacturing process known as turning, which involves rotating a steel workpiece on a lathe while a cutting tool removes material to achieve the desired shape and dimensions. This method is favored for its ability t

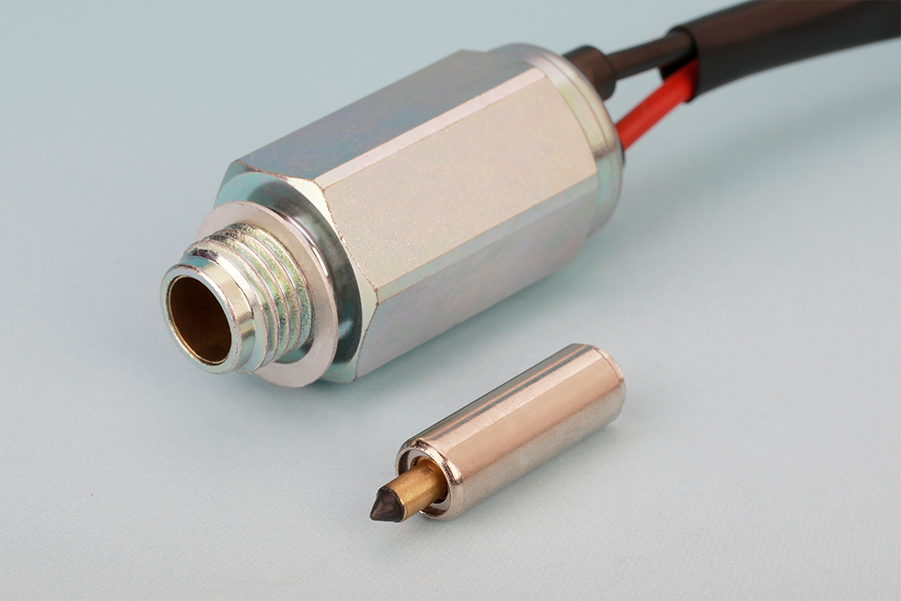

Steel turned parts are vital components in various industries, especially within the realm of precision engineering and mechanical hardware processing. These parts typically undergo a manufacturing process known as turning, which involves rotating a steel workpiece on a lathe while a cutting tool removes material to achieve the desired shape and dimensions. This method is favored for its ability to produce highly accurate and consistent components, making it an ideal choice for critical applications.

One of the primary benefits of steel turned parts is their strength and durability. Steel, known for its exceptional mechanical properties, can withstand high stress and resist wear and tear, making it suitable for demanding environments such as automotive, aerospace, and industrial machinery applications. By utilizing high-quality steel grades, manufacturers can ensure that the turned parts meet specific mechanical requirements, further enhancing their performance.

In addition to strength, steel turned parts offer a high degree of precision. The turning process allows for tight tolerances, which is essential for applications where fit and function are crucial. This level of accuracy is particularly important in industries like medical device manufacturing, where even minor discrepancies can lead to significant operational issues. Furthermore, advanced CNC (Computer Numerical Control) machining techniques enable the production of complex geometries and intricate designs, further broadening the application scope of steel turned parts.

Another advantage of steel turned parts is their adaptability. These components can be tailored to meet specific design requirements, including surface finishes, coatings, and heat treatments. This versatility makes it possible for engineers and designers to create custom solutions that cater to unique operational needs, enhancing overall product performance. Additionally, the ability to fabricate parts in various sizes ensures that manufacturers can accommodate both small-scale and large-scale production runs effectively.

When considering steel turned parts, several factors must be taken into account to ensure optimal results. Material selection is crucial, as different steel grades exhibit distinct properties that may be better suited for specific applications. Moreover, machining parameters such as cutting speeds, tool materials, and coolant usage can significantly influence the final quality of the turned parts. Therefore, collaborating with experienced manufacturers who understand these intricacies can lead to improved efficiency and reduced production costs.

In conclusion, steel turned parts play a critical role in the modern manufacturing landscape, offering unmatched strength, precision, and adaptability. By understanding their applications and benefits, businesses can harness the full potential of these components to enhance product performance and drive innovation in their respective industries.

One of the primary benefits of steel turned parts is their strength and durability. Steel, known for its exceptional mechanical properties, can withstand high stress and resist wear and tear, making it suitable for demanding environments such as automotive, aerospace, and industrial machinery applications. By utilizing high-quality steel grades, manufacturers can ensure that the turned parts meet specific mechanical requirements, further enhancing their performance.

In addition to strength, steel turned parts offer a high degree of precision. The turning process allows for tight tolerances, which is essential for applications where fit and function are crucial. This level of accuracy is particularly important in industries like medical device manufacturing, where even minor discrepancies can lead to significant operational issues. Furthermore, advanced CNC (Computer Numerical Control) machining techniques enable the production of complex geometries and intricate designs, further broadening the application scope of steel turned parts.

Another advantage of steel turned parts is their adaptability. These components can be tailored to meet specific design requirements, including surface finishes, coatings, and heat treatments. This versatility makes it possible for engineers and designers to create custom solutions that cater to unique operational needs, enhancing overall product performance. Additionally, the ability to fabricate parts in various sizes ensures that manufacturers can accommodate both small-scale and large-scale production runs effectively.

When considering steel turned parts, several factors must be taken into account to ensure optimal results. Material selection is crucial, as different steel grades exhibit distinct properties that may be better suited for specific applications. Moreover, machining parameters such as cutting speeds, tool materials, and coolant usage can significantly influence the final quality of the turned parts. Therefore, collaborating with experienced manufacturers who understand these intricacies can lead to improved efficiency and reduced production costs.

In conclusion, steel turned parts play a critical role in the modern manufacturing landscape, offering unmatched strength, precision, and adaptability. By understanding their applications and benefits, businesses can harness the full potential of these components to enhance product performance and drive innovation in their respective industries.

Related content