Understanding Steel Turned Parts: Essential Components in Precision Engineering

Release Time:

Jun 08,2025

Steel turned parts are precision-engineered components crafted from steel, commonly used in a variety of applications across numerous industries. These parts are typically produced using a process known as turning, where a rotating workpiece is shaped by a stationary cutting tool. This method allows for high levels of precision and efficiency, making it ideal for producing complex shapes and tight

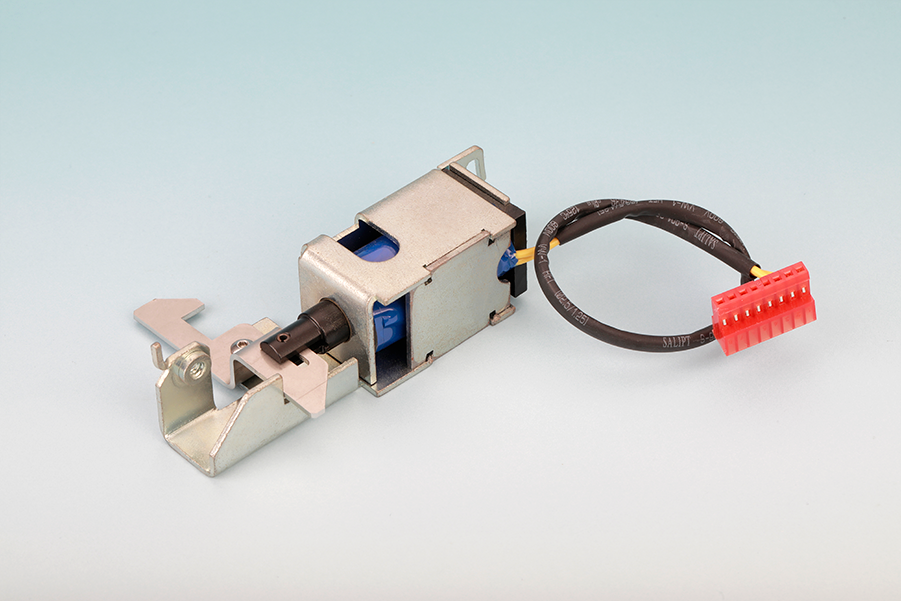

Steel turned parts are precision-engineered components crafted from steel, commonly used in a variety of applications across numerous industries. These parts are typically produced using a process known as turning, where a rotating workpiece is shaped by a stationary cutting tool. This method allows for high levels of precision and efficiency, making it ideal for producing complex shapes and tight tolerances that are often required in mechanical components.

One of the primary advantages of steel turned parts is their robustness and durability. Steel is known for its strength and resilience, making it an excellent choice for components that must withstand heavy loads and harsh environmental conditions. From automotive to aerospace applications, the reliability of steel turned parts is critical in ensuring the overall performance and safety of machinery and equipment.

The manufacturing process of steel turned parts involves several key steps. First, the choice of steel grade is essential, as different grades offer varying mechanical properties. After selecting the appropriate material, the turning process begins, typically on a CNC lathe, which enhances precision and repeatability. During turning, the cutting tool removes material from the rotating workpiece to achieve the desired shape and dimensions.

In addition to turning, various secondary operations may be performed to enhance the functionality of these parts. These operations can include drilling, threading, and milling, which further refine the product and tailor it to specific requirements. Quality control is also paramount; after manufacturing, steel turned parts undergo rigorous testing to ensure they meet industry standards and specifications.

The applications of steel turned parts are vast. In the automotive sector, they are used in engine components, transmission parts, and suspension systems, where precision is crucial for performance and safety. In the aerospace industry, steel turned parts contribute to structural integrity and functionality, found in everything from landing gear to engine mounts. Furthermore, machinery manufacturers rely on these components for various equipment, from industrial machines to robotics, highlighting their versatility and importance.

In conclusion, steel turned parts are indispensable in modern manufacturing and engineering. Their production through advanced techniques like CNC turning ensures high precision and quality, making them suitable for a broad range of applications. Understanding the intricacies of steel turned parts can empower professionals in the machinery and hardware processing sectors to make informed decisions regarding material selection and manufacturing processes. As industries continue to evolve, the demand for high-quality steel turned parts will undoubtedly remain a cornerstone of precision engineering.

One of the primary advantages of steel turned parts is their robustness and durability. Steel is known for its strength and resilience, making it an excellent choice for components that must withstand heavy loads and harsh environmental conditions. From automotive to aerospace applications, the reliability of steel turned parts is critical in ensuring the overall performance and safety of machinery and equipment.

The manufacturing process of steel turned parts involves several key steps. First, the choice of steel grade is essential, as different grades offer varying mechanical properties. After selecting the appropriate material, the turning process begins, typically on a CNC lathe, which enhances precision and repeatability. During turning, the cutting tool removes material from the rotating workpiece to achieve the desired shape and dimensions.

In addition to turning, various secondary operations may be performed to enhance the functionality of these parts. These operations can include drilling, threading, and milling, which further refine the product and tailor it to specific requirements. Quality control is also paramount; after manufacturing, steel turned parts undergo rigorous testing to ensure they meet industry standards and specifications.

The applications of steel turned parts are vast. In the automotive sector, they are used in engine components, transmission parts, and suspension systems, where precision is crucial for performance and safety. In the aerospace industry, steel turned parts contribute to structural integrity and functionality, found in everything from landing gear to engine mounts. Furthermore, machinery manufacturers rely on these components for various equipment, from industrial machines to robotics, highlighting their versatility and importance.

In conclusion, steel turned parts are indispensable in modern manufacturing and engineering. Their production through advanced techniques like CNC turning ensures high precision and quality, making them suitable for a broad range of applications. Understanding the intricacies of steel turned parts can empower professionals in the machinery and hardware processing sectors to make informed decisions regarding material selection and manufacturing processes. As industries continue to evolve, the demand for high-quality steel turned parts will undoubtedly remain a cornerstone of precision engineering.